In-Mold Decorations in Modern Manufacturing: A Comprehensive Guide

Wiki Article

Mastering In-Mold Decorations: Methods, Patterns, and Ideal Practices for Ideal Outcomes

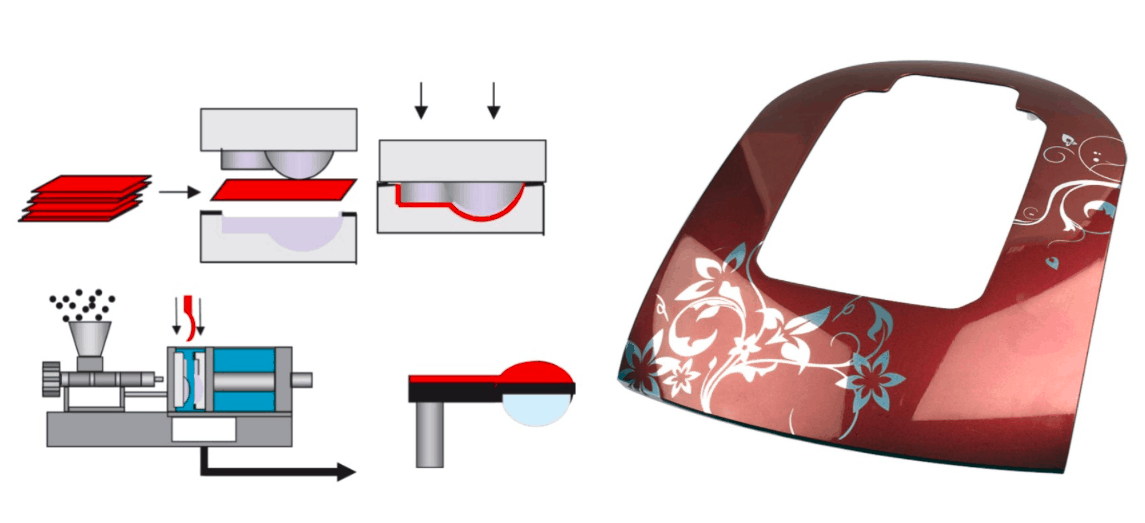

In the realm of manufacturing, the art of in-mold designs stands as an essential facet of item layout and production. In-Mold Decorations. By delving into the strategies, trends, and finest methods that underpin successful in-mold design processes, services can open a world of opportunities that not only raise the aesthetic appeal of their products however likewise improve production effectiveness and reinforce consumer engagement.Material Option

Product selection is a crucial facet of grasping in-mold decorations, as it straight impacts the top quality and sturdiness of the last product. When picking materials for in-mold decors, it is necessary to consider variables such as compatibility with the molding process, the wanted aesthetic result, and the ecological conditions the item will deal with.In addition, products with high warmth resistance are favored for in-mold decors, especially for products that will be exposed to elevated temperatures during their lifecycle. By carefully selecting the appropriate material for in-mold decorations, manufacturers can enhance the overall quality and resilience of their products, meeting the expectations of both end-users and customers - In-Mold Decorations.

Layout Technology

A crucial variable in progressing the area of in-mold designs is the continuous exploration and execution of layout technology techniques. Design technology plays a critical duty in improving the aesthetic appeal, capability, and total high quality of products manufactured making use of in-mold design processes. By incorporating cutting-edge style elements, manufacturers can separate their products in the market, bring in customers, and stay in advance of competitors.One of the key facets of style innovation in in-mold decors is the combination of intricate patterns, appearances, and graphics that were previously testing to accomplish with traditional decor techniques. Advanced modern technologies such as 3D printing and electronic design devices enable developers to create facility and detailed layouts that can be perfectly moved onto molded components. Additionally, making use of vibrant shades, metal surfaces, and unique effects like gloss or matte structures can further raise the aesthetic charm of in-mold enhanced products.

Moreover, layout development expands beyond aesthetics to include useful enhancements such as ergonomic forms, incorporated features, and adjustable components that accommodate certain customer needs. By accepting layout innovation, makers can open new possibilities for customization, creative thinking, and product distinction in the affordable landscape of in-mold decors.

Manufacturing Efficiency

Efficient production processes are crucial for converting the innovative designs developed in the field of in-mold decorations right into premium ended up items that fulfill market needs and customer assumptions. In the world of in-mold designs, manufacturing effectiveness includes different crucial elements that contribute to the general success of the manufacturing process. One website here essential element is the optimization of mold style and tooling to guarantee exact and smooth design transfer onto the end product. By fine-tuning mold and mildew arrangements and spending in top notch tooling products, suppliers can improve effectiveness and consistency in manufacturing.In addition, carrying out automation and robotics in the assembly line can significantly boost effectiveness by streamlining recurring tasks and lowering the margin of error. Automation not just speeds up the manufacturing process but likewise enhances accuracy and repeatability, leading to a much more uniform and top notch final result. In addition, embracing lean production principles, such as just-in-time supply management and waste decrease strategies, can additionally boost production performance by minimizing downtime and enhancing source usage. In general, an alternative strategy to production effectiveness is paramount in making best use of the possibility of in-mold decor techniques and achieving optimal cause the open market landscape.

High Quality Control Procedures

What are the key methods for guaranteeing stringent top quality control steps in the world of in-mold designs? Quality control actions are vital in in-mold decoration procedures to guarantee the manufacturing of flawless and high-grade completed items.Utilizing sophisticated technologies such as automatic inspection systems can likewise boost the quality control procedure by offering exact and dependable data for evaluation. These systems can detect flaws that might be missed by hands-on assessments, thereby enhancing total product quality and uniformity.

Normal training and development programs for workers entailed in the in-mold decor process can likewise add to keeping top quality requirements. By enlightening team on best methods, high quality assumptions, and the relevance of attention to detail, business can promote a society of high quality awareness throughout the company.

Consumer Appeal

To improve the marketability of in-mold decor products, catering and understanding to customer preferences play an essential function in determining their allure and success. Providing customization alternatives such as customized layouts, color variants, and textural aspects can significantly boost the appeal of in-mold decor products.

Final Thought

In-mold designs provide a flexible and efficient means Look At This to improve product visual appeals. Mastering in-mold decors needs an alternative approach that takes into consideration all aspects of the production process to guarantee success.In the world of production, the art of in-mold designs stands as a critical aspect of item style and production. Layout development plays an essential role in boosting the aesthetic Get More Information allure, performance, and overall top quality of products made utilizing in-mold decoration procedures.One of the key facets of style innovation in in-mold designs is the integration of complex patterns, textures, and graphics that were formerly challenging to accomplish with traditional decor methods.Reliable production procedures are essential for equating the innovative styles created in the field of in-mold decors into high-quality completed items that meet market needs and customer expectations. Using customization choices such as tailored designs, color variants, and textural elements can considerably boost the appeal of in-mold design items.

Report this wiki page